China Best Sapphire Vacuum Window Factories Pricelist – Precision Sapphire Window – Optic-Well

China Best Sapphire Vacuum Window Factories Pricelist – Precision Sapphire Window – Optic-Well Detail:

Optic-well offer a wide range of sapphire windows not only for Consumer Products and Industrial Area. We also supply precision sapphire windows for Labs, Research Institutions, Precision Optical Instruments Manufacturer. Our Precision Sapphire Windows buyer have a lot request in common. Here we list some important specification for your reference.

Surface Quality: According to the US military standard MIL-PRF-13830, two sets of numbers are used to indicate the size of surface defects. For example, use the former 40/20 to limit the size of scratches, and the latter to limit the size of pits. Usually precision sapphire windows request surface quality equal or above S/D 60/40

Surface Flatness: Surface Flatness refers to the deviation of the macroscopic convexity of the substrate from the standard template. Flatness is an index that limits the amount of change between the measured object and standard template, and is used to control the shape error of the measured objects.

We use flat crystal interferometry to test our products. The working surface of the optical flat crystal is used to reflect the ideal plane, and the degree of curvature of the interference fringe is directly used to determine the flatness error value of the measured surface. The number of interference fringes formed between the measured object and the standard template when using the flat crystal interferometry. The optical path difference of half a wavelength forms an aperture , So we usually use λ to express the surface flatness of optical surfaces. Best we can do λ/10 @633nm.

Parallelism: Means the wedges between two flat surfaces. Best can be up to in 2 arcseconds .

For more information, please contact our sellers.

We have some stocked precision sapphire windows, please check the following list and contact us if you just want to buy them.

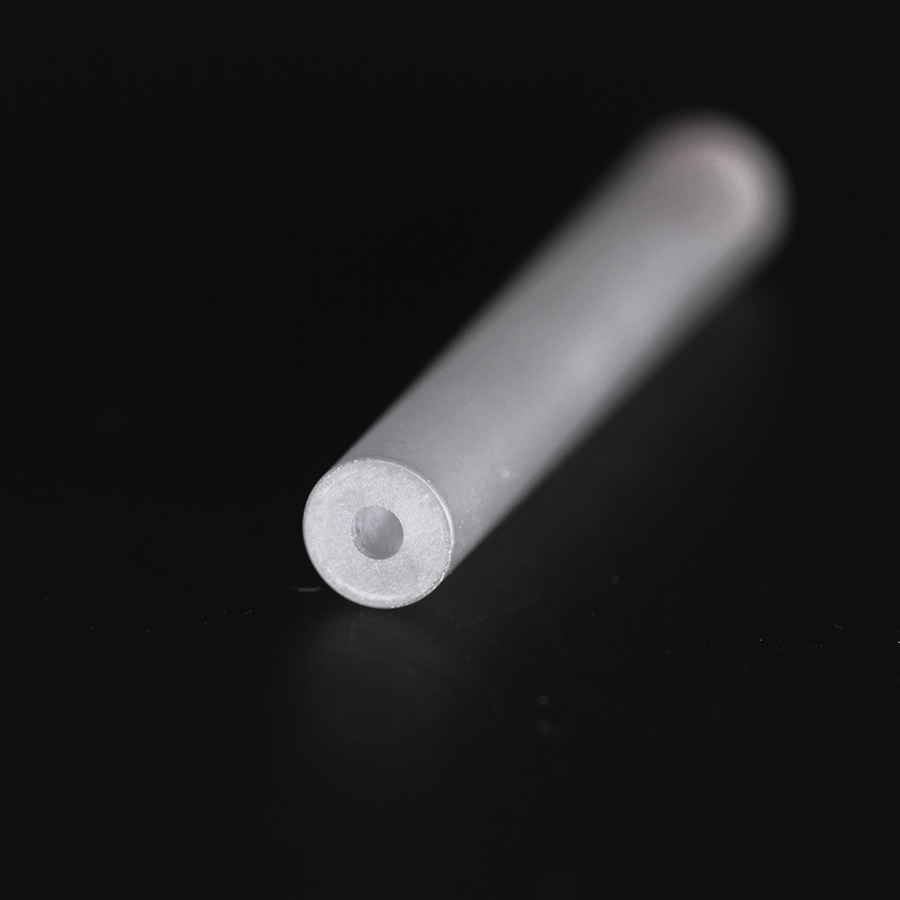

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for China Best Sapphire Vacuum Window Factories Pricelist – Precision Sapphire Window – Optic-Well , The product will supply to all over the world, such as: Indonesia, Ghana, UK, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!