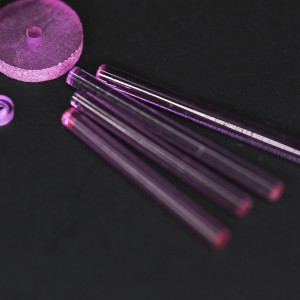

Synthetic Ruby Rods For Laser Equipment

Ruby also called red sapphire, because of the impurity(Cr2O3) made the synthetic sapphire shows red color. The size of Ruby is limited by it's grow method, for now the maximum size Ruby rod we can supply is around D50 x 50mm. Ruby is crisper than white sapphire, so ruby has more limited on production.

Optic-Well Sapphire supplies flame melting method Ruby Parts. and you are welcome to send us your drawings and your requests for RFQ.

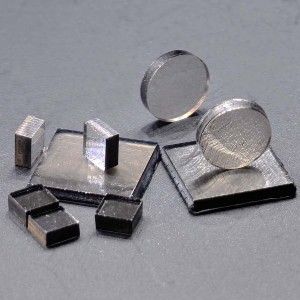

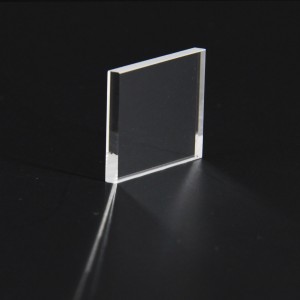

As Ruby has similar physical properties with white sapphire, we can do most shapes as white sapphire can do. Basically polishing for flat surface is easy, and can be highly polished if customer want to use as optical parts. Round surface also can be polished, but not as high standard with flat surfaces while common usages only need round surface transparent.

Ruby rod can be used as the main body of ruby laser, as the main body of the laser ruby rod optical quality requirements are very high, the two ends of the rod grinding and polishing into an optical parallel plane, its parallelity requirements are better than 10 seconds, plane not less than 1/4 aperture, end face and rod shaft verticality is not less than 1 point, side not polished, to prevent the generation of parasitic laser oscillation.